In order to remain competitive in a fleetly changing artificial geography by 2025, manufacturing companies will need intelligent intertwined systems. heritage systems and traditional operation styles frequently fail to meet global force chains, product planning and resource planning challenges. This is when ERP in manufacturing becomes pivotal.

Enterprise Resource Planning( ERP) software is a centralized system that connects all aspects of a manufacturing operation from procurement, product,force and logistics through to finance and client services.ERP software for the manufacturing industry sector allows companies to maximize effectiveness and reduce waste. They can also gauge up their operations more snappily.

This guide explains how ERP can help manufacturers maximize their output and efficiency. It includes the most important modules, such as project planning, software project management and supply chain management.

The stylish ERP software for manufacturing industry is acclimatized to the requirements of manufacturing businesses. It gives real- time data about the shop bottom, labor and material operation.

An ERP system that's robust for the manufacturing sector will ensure that departments are working together within an intertwined frame. This allows for a flawless data exchange, smarter opinions and briskly responses to changes.

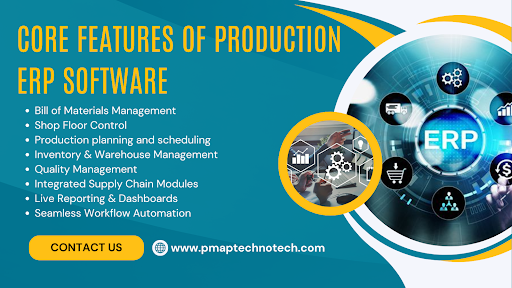

Numerous features of the product ERP software are in line with manufacturing processes. It reduces inefficiencies and enables a data- driven operation.

Bill of Accoutrements Management is an integral point of any manufacturing software. It involves maintaining and creating a list of raw accoutrements ,sub-assemblies and factors as well as the amounts needed to produce a final product.

A BOM is a design for manufacturing. It guides the product, procurement and force departments through the product lifecycle.

Protect Floor Control, also called Shop Floor Management( SFC), is a collection of tools, systems, and processes used to optimize and manage products in the plant. It's an integral part of the ERP software for manufacturing industry, allowing real- time visibility to all aspects between raw material input and final product affair.

Production Planning and Scheduling is a critical function at the heart of every manufacturing unit. The design is what determines when, how important and what you'll produce. An ERP makes this planning more intelligent and data- driven, as well as responsive to real- time changes.

Stock and storehouse operation are critical factors in any manufacturing setup. This directly impacts the product effectiveness, cost operation and client satisfaction. Without accurate force shadowing, manufacturers face issues like stockouts or overstocking. The manufacturer may also face detainments in shipments or capital blockages

ERP- enabled Inventory & Warehouse Management can be a game changer for this assiduity.

Examiner quality checks and define examination criteria. corroborate compliance with instruments.

ERP for products allows manufacturers to have full control of the product cycle, from beginning to end. This results in a raised affair and reduced time-out.

Project planning in Software Project Management launching new product lines, setting up manufactures, or enforcing a spare product process.

Businesses can:

Project Management Software for Manufacturing ensures timely deliveries, optimal resource allocation, and real- time collaboration work. This results in quicker product cycles and lower costs.

The force chain is at the core of every manufacturing operation. Planning can lead to detainments in shipments, dearths of force or high costs.

ERP is n't complete without force chain operation software. ERP modules for force chain operation include:

ERP Software's Supply Chain Management allows you to optimize translucency and sourcing while creating a force network that's flexible to change.

Enforcing ERP software for manufacturing industry has both political and strategic advantages. These have a direct impact on profitability, sustainability, and scalability.

The stylish ERP software for manufacturing industry will transfigure your plant into an nimble, digital and data- driven machine.

Consider the following when choosing the best ERP software for manufacturing business:

Ultramodern ERP software for manufacturing industry can be acclimatized to meet the requirements of individual manufacturers, including their processes, workflows and pretensions. Manufacturing businesses differ in terms of assiduity, product complexity and product capacity. They also vary by pool dynamics, nonsupervisory conditions, and the type of business. Customization is no longer a luxury, but a necessity.

Pall ERP, which is hosted ever and accessible via the Internet, offers easy updates, lower up- front costs, and remote access. This is ideal for companies that want flexibility and scalability.

On- premise ERP is installed on the company's waiters. It gives further control and customization, but also requires further conservation, structure and IT staff.

Mobile ERP allows manufacturers to cover products, access real- time information, manage workflows and authorize tasks, using their smartphones or tablets. This allows for faster opinions, lesser dexterity and continued operations, indeed when on the move.

Integrate your ERP seamlessly with third- party tools, similar as CRM, IoT, Finance, Inventory, and other departments. This will ensure a smooth data inflow, unified operations, and flawless operations in all departments.

AI and robotization revise diligence by enabling intelligent decision- making and reducing homemade work while perfecting delicacy. They drive manufacturing effectiveness through robotic process robotization, real- time monitoring and prophetic conservation. These technologies are n't only a boost to productivity, but they also allow businesses to gauge briskly and with lower crimes. In today's tech- driven, presto- paced world, AI and robotization are crucial to digital metamorphosis.

PMAP Technotech specializes in the development of Custom ERP software for manufacturing industry.

Our ERP solutions are tailored to fit your specific business needs, not the other way round.

Construction and engineering is a complex endeavour. It involves multiple brigades, changing design deadlines and budgets, resource operation, subcontractors and compliance. For enterprises to manage this effectively, they're turning to assistance-specific ERP software for manufacturing industry.

A Construction & Engineering ERP centralizes and integrates all critical functions, including design planning, procurement and labor operation. It also includes budgeting, tracking outfit, nonsupervisory compliance, and budgeting.

Automotive components are individual parts or assemblies that combine to form a vehicle. They include everything from the smallest screws to the most complex electronic systems, brakes, transmissions, and engines. Automotive companies either manufacture these components in-house or source them from component suppliers and manufacturers.

Each part has a role to play in the safety, performance and functionality of a car. Automotive components are a complex and vast industry, requiring high precision engineering, strict quality control and extensive supply-chain coordination.

Chemical and Pharmaceutical Industry is one of utmost regulated and processes- driven industriousness in the world. It's a high- trouble terrain, where safety, quality, compliance and perfection are n't negotiable.

Manufacturers in this sedulity are constantly under pressure to maintain a balance between invention and control. From managing batch- position phrasings, to icing shelf- life monitoring and adhering to strict government regulations like FDA, GMP or ISO, they must always find a way to manage both.

The cloth and garment assiduity is one the most dynamic, labor- ferocious diligence in the world. The cloth and vesture assiduity encompasses all aspects of the fabric life cycle, from the procurement of raw accoutrements ( similar as cotton, hair or synthetic filaments), to the product of the garments that consumers wear.

The assiduity is at the crossroads of manufacturing, design and retail and plays an important part in husbandry around the world, especially in India, Bangladesh, China and Vietnam.

Answer: By automating workflows and tracking shop floor conditions in real-time, product ERP software reduces inefficiencies. It reduces time-outs, improves machine uptime and streamlines operations throughout the plant.

Answer: While a general Production ERP software system covers finance, HR, and basic operations, Production ERP focuses on manufacturing-specific needs such as scheduling, shop floor monitoring, raw material tracking, and quality checks. It's designed for discrete, mixed-mode, and process manufacturing industries.

Answer: The ERP software is designed for the manufacturing industry and includes modules such as order processing, product scheduling, storehouse & force operation, quality control, software design planning, and force chain ERP.

Answer: ERP supply chain operations include demand forecasting, smart procurement and supplier evaluation. They also provide real-time payload shadowing as well as force synchronization. This allows for a cost-effective and flexible force chain to adapt to demand oscillations.

Answer: Yes. ERP can be adapted to SMEs and is scalable for the manufacturing industry. Pall-based ERP results are particularly cost-effective. They offer inflexibility, lower structure costs, as well as easy remote access.

Answer: Pall ERP for manufacturing offers remote access, scalability and lower outspoken investments. On-premise ERP offers advanced control and customisation but requires a new structure and IT conservation.

Answer: The ERP system for the product has built-in quality tools to cover all checkpoints and ensure compliance with standards (ISO, GMP, FDA) as well as minimize defects. It improves the overall quality of products and customer satisfaction.

Answer: Yes. Ultramodern ERP software allows for customization of diligence, similar to automotive factors. Each ERP module is able to be customized for unique compliance and workflow conditions.

Answer: Mobile ERP software allows real-time monitoring of product schedules and blessings as well as workflow operations via smartphones or tablets. Directors can make quicker decisions and keep operations running nonstop.

Answer: PMAP Technotech, a leading ERP development company in India, is known for its moxie when it comes to product ERP, force chain ERP, and software design operations. Their ERP systems are customizable and scalable to maximize manufacturing diligence.

The plant of the future will be:

Manufacturers must move from fractured software to an intertwined ERP ecosystem in order to survive and prosper in the current period.

YYou can achieve excellence by integrating ERP software for product, design operation software and ERP software for force chain operation.

ERP software for manufacturing industry. It's an investment in the future of your plant. The right ERP result can help you to stay ahead of your competition by enabling invention and boosting productivity.

Reduce supereminent times. Want to gauge up operations without chaos or confusion?

Need better control of force chains?

It's time for you to mate up with PMAP Technotech.

We produce acclimatized ERP results for manufacturing diligence across India that produce real results.