Indian manufacturing has reached a critical point. The rising costs of raw materials, the tightening delivery deadlines, GST compliance requirements, and increasing competition, both domestically and globally, are forcing manufacturers to change their business models. Manual processes, scattered sheets, and disconnected systems are not enough.

Profitability is directly affected by production delays, inventory loss, and lack real-time visibility. Manufacturing companies in India, both MSMEs and large corporations, are adopting ERP software for manufacturing to improve control, efficiency, scalability, and scale.

This guide will explain what manufacturing ERP is and why it is important. It will also tell you how much it costs in India. And how to select the best ERP vendor.

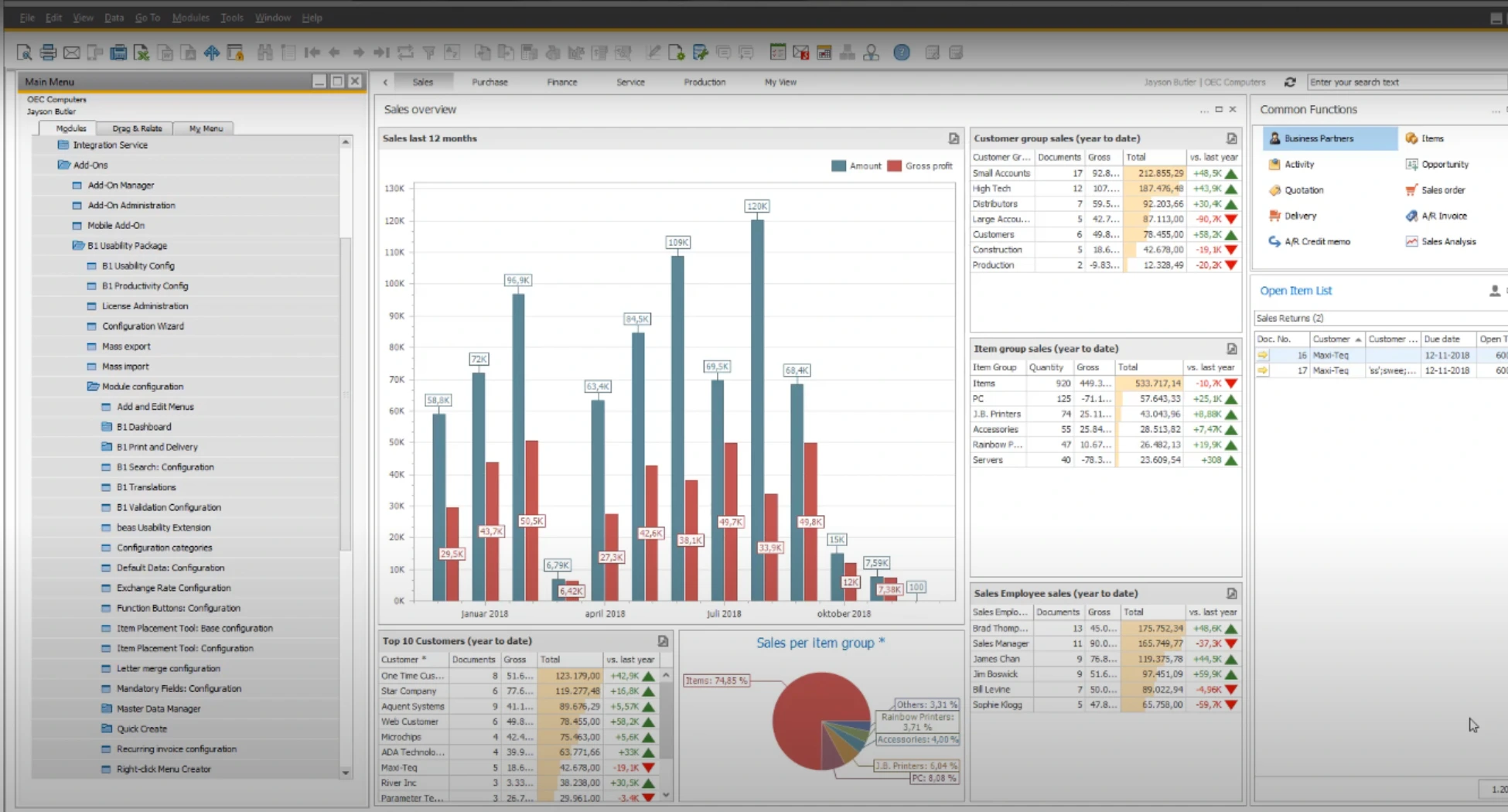

ERP software is a central digital system that manages, integrates, and streamlines all manufacturing core operations on a single platform. It links departments like production, inventory management, procurement, quality assurance, finance, sales and supply chain to ensure that all functions are working with the same real-time accurate data.

ERP is more than just basic business management in a manufacturing environment. It was designed to manage production planning, materials requirements, shop floor activities, and cost controls. ERP allows for complete visibility throughout the manufacturing process, from creating work orders to scheduling machines, tracking raw materials and work-in-progress, to tracking finished goods.

Contrary to general business software, ERP for manufacturing supports Bill of Materials, batch and lot tracking and routing. It also checks quality and meets compliance requirements. It allows manufacturers to plan their production more efficiently and reduce waste, while maintaining consistent product quality. Dashboards and reports in real-time help managers to monitor performance, identify bottlenecks and make quick decisions.

ERP software is also crucial for Indian manufacturers in terms of GST compliance and statutory reports. Automated tax calculations and audit trails, as well as automated invoicing, reduce the manual effort required and minimize errors. This ensures smoother regulatory compliance.

ERP is a powerful tool that acts as the single source of information for an entire organization. It improves the coordination between departments and increases productivity by eliminating manual processes and data silos. ERP software for manufacturing is a technological foundation that allows a manufacturing unit to compete, grow, and operate more efficiently.

| General ERP | Manufacturing ERP |

|---|---|

| Generic Business Processes | Workflows specific to industry |

| Limited production features | Planning for advanced production |

| Basic Inventory | BOM, batch, lot & WIP tracking |

| Minimum Quality Control | Integrated Quality Management System |

| Focus on the customer, not the factory | The ‘Shop Floor Operation’ is designed for the shop floor |

ERP software for manufacturing is built specifically to handle production cycles, material planning, machine utilization, quality checks, and compliance—something general ERP systems struggle with.

Manufacturers who still use manual or semi-automated machines face persistent operational challenges.

The data entered on multiple spreadsheets can lead to errors such as duplication and mismatches.

Planning and scheduling are essential to ensuring that machines run efficiently, materials are available and deadlines are met.

Under-stocking can halt production and over-stocking can block working capital. Both are detrimental to profitability.

It is difficult to control costs or plan growth when you lack real-time insight.

These issues can compound over time and affect customer satisfaction, margins and sustainability.

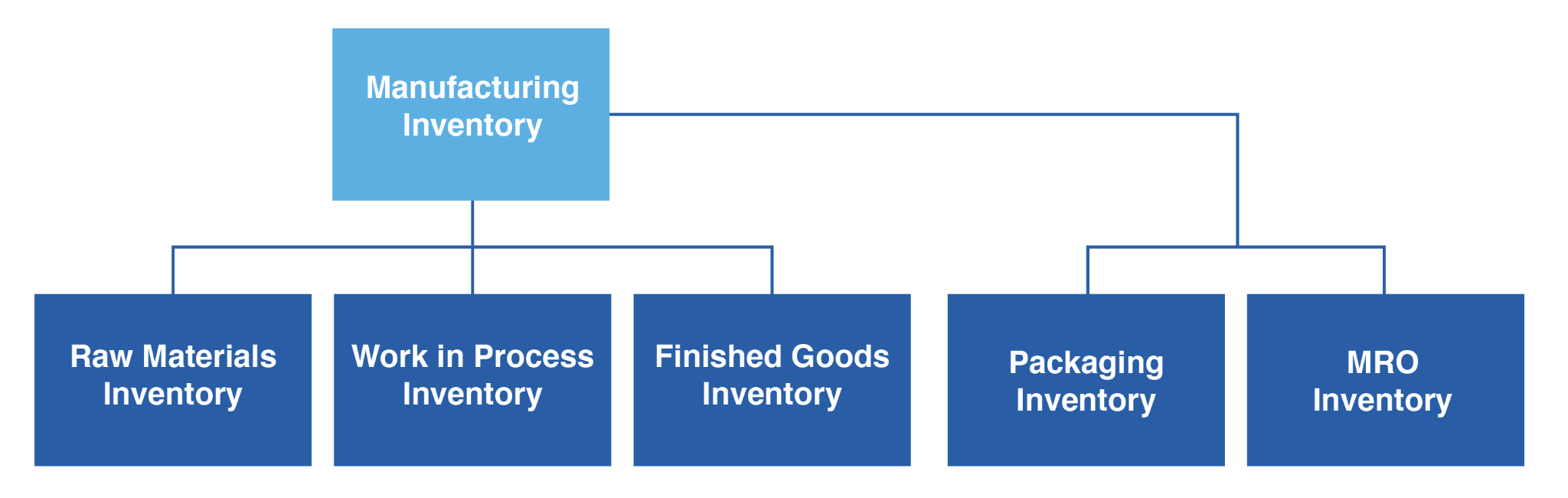

The modules of a robust ERP system for manufacturing work seamlessly together.

This will ensure that you get your product on time and with the best possible use of resources.

This eliminates the need for guesswork, and it prevents stock-related interruptions.

For industries such as automotive, pharmaceutical, food and textiles, it is essential.

Enhances supplier coordination and procurement efficiency.

Assures compliance with statutory requirements and financial transparency.

Indian manufacturers cannot rely on manual records or fragmented systems in today's highly competitive and fast-paced manufacturing environment. ERP software is a digital backbone connecting all departments, from the shop floor to finance, bringing consistency, clarity and control to daily operations. Here is a detailed description of how ERP benefits manufacturing companies in India.

Cost optimization is one of the most visible and immediate benefits of ERP software. ERP software for manufacturing integrates procurement, inventory management, production and finance to eliminate unnecessary expenditures caused by excess stock, over-ordering of raw materials and emergency purchases made at the last minute. The manufacturers can see where the money is going and where it's being wasted. Accounting automation, accurate cost allocation and real-time tracking of expenses help managers make financial sound decisions. This improves margins and cash flows.

ERP can deliver measurable business benefits.

Dashboards give you real-time insight into your production, inventory, sales and finances. No need to wait for monthly reports.

GST, audit trails and regulatory reporting are now simpler and more accurate.

ERP can grow with your business - new plants, users and modules can easily be added.

Small and midsize manufacturers can benefit from:

Large manufacturers need:

It is important to choose an ERP that fits your size, current growth and future plans.

PMAP Technotech offers customized ERP solutions for Indian manufacturing environments.

ERP tailored to your industry--automotive, textile, food processing, engineering, or FMCG.

GST reporting and audit-ready system built-in.

Implementation, training and support on-site ensure smooth adoption, resulting in a faster ROI.

PMAP Technotech tailors ERP to the business processes of your company, rather than forcing you to change your software.

| Business Size | Cost Range |

|---|---|

| Small Manufacturing | 2–6 Lakhs Rupees |

| Mid-Size Manufacturing | 6–15 Lakhs Rupees |

| Large Enterprises | ₹15 Lakhs+ |

The cost of customization, the number of users and modules will vary.

ERP ROI is derived from:

The average ROI for ERP investments is 12-24 months.

The wrong ERP vendor could cost you more than just the software.

ERP software in India is not a luxury anymore. It's an essential business tool for manufacturers. The right ERP software for manufacturing can help you achieve efficiency, control and growth, whether you are an MSME that wants to streamline its operations, or an enterprise looking for digital transformation.

The key lies in selecting a manufacturing-focused ERP partner who understands Indian business realities--not just technology.

PMAP Technotech can help you discover how ERP will transform your manufacturing operation. Expert guidance, transparent pricing and a solution tailored to your business are all available.

Answer: ERP software for manufacturing companies in India is an integrated system that manages production, inventory, quality, finance, GST billing, and supply chain operations on a single platform. It gives manufacturers real-time visibility, better control, and improved operational efficiency.

Answer: ERP helps reduce production delays, control inventory, automate GST compliance, minimize manual errors, and improve decision-making, making manufacturing operations more profitable and scalable.

Answer: The cost of ERP software in India generally starts from ₹2–6 lakhs for small manufacturers, ₹6–15 lakhs for mid-size companies, and ₹15 lakhs+ for large enterprises, depending on customization, modules, and number of users.

Answer: Yes. Modular ERP solutions are ideal for MSMEs as they are affordable, quick to implement, and help improve cash flow, inventory accuracy, and customer fulfillment.

Answer: Most manufacturing companies start seeing ROI within 12 to 24 months through reduced inventory costs, fewer production delays, lower rework, and faster billing and collections.